1. Application

The specification describes the type, performance, test conditions, precautions, shelf life, transportation methods, and technical consulting conditions of the model 43184 / 24V360Ah- 8S18P lithium iron phosphate battery packs for power. The specification is applicable to the 43184 / 24V360Ah lithium-ion battery pack developed and produced by Nantong Ningyuan Automation Technology Co,Ltd. based on 43184 / 20Ah lithium ion cells.

2. Type & Model

Type:Lithium Iron Phosphate Battery Pack

Model:43184 -24V360AH

3. Single Cell Parameter

Item | Specification |

Nominal Capacity | 20Ah |

Nominal Voltage | 3.2V |

Resistance | ≤ 4mΩ |

Standard Charge Current | 1C |

Max Charge Voltage | 3.65V |

Standard Discharge Current | 1C |

Continuous Discharge Current | 3C |

End-Off Discharge Voltage | 2.5V |

Working Temp. | -20~60℃ |

Cell Diameter | 43±0.5mm |

Cell Height | 184 |

Weight | ≤530±5g |

Charge Temp Range | 0℃~45℃ |

Discharge Temp Range | -20℃~55℃ |

Storage Temp Range | -10℃~45℃ |

4. Battery pack performance

Model | 43184/ 24V360Ah |

Connector Method | 144 pcs43184 cells in series and Parallel |

Nominal Capacity(AH) | 360Ah |

Rated Volt(V) | 24 V |

Over-Voltage Alarm value | 29.2V |

Over-Voltage Alarm Recovery value | 27.2V |

Over-Voltage protection value | 29.6V |

Under-voltage alarm value | 22.4V |

Under-voltage Alarm Recovery value | 24.4V |

Under-voltage protection value | 20.8V |

Under-voltage protection recovery value | 22.8V |

Rated Power(Wh) | 8.64kWH |

Operation Temp Range | 0℃~50℃ |

Max Charge Volt | 29.2V |

End-off Discharge Volt | 20.8V |

Max Charge Current | 360A |

Max Continuous Output Current | 720A |

Protection Type(PCB) | Over-Charge, over-discharge, over-current, short circle |

Operation Humidity | <90% |

House Material | Metal |

5.Test Conditions

Experiments and measurements are performed at standard temperature (20±5°C) and standard humidity (65±20%).

Standard charging: Charging with a matching charger, charging is stopped when the indicator light changes from red to green.

Standard discharge: Constant current at 0.2C discharged to 20.8V.

6. Performance

6.1 Exterior

The outer surface of the battery is clean, no electrolyte leakage, no obvious scratches and mechanical damage, no deformation, no corrosion of the contacts, There are no other appearance defects that affect the battery's value, and the surface has the necessary product identification.

6.2 Performance

Item | Testing process | Standard |

Open circle Volt | Test the open circle voltage in 1 hour after standard charge | 29.2V |

Nominal Capacity | Discharge to 20.8V by CC at 0.2C in 5 hours after standard charge | Capacity≥360Ah |

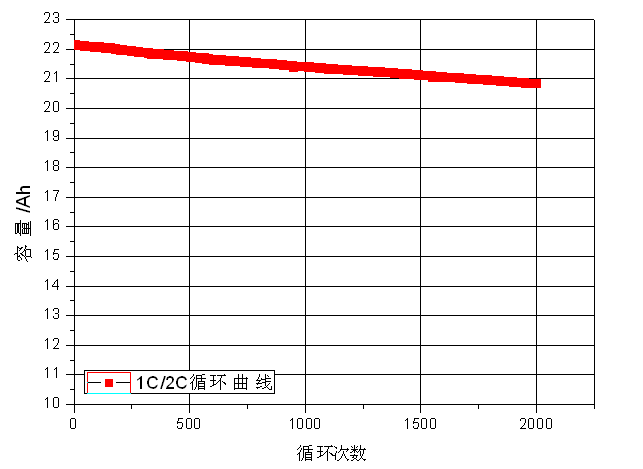

Charge-Discharge Cycle Life | The cycle life is end when the 2 consecutive times discharge time less than 1.6hours according to standard charge-discharge cycle at 25±5℃ | ≥2000cycles |

Soc | Stay 28 days at 25±5℃ after standard charge, then discharge to end-off voltage at 0.2C, the discharge capacity ≥90% nominal capacity | Capacity≥324Ah |

High Temp performance | Stay 4 hours at 60±2℃ after standard charge, then discharge to end-off voltage at 0.2C, the discharge capacity ≥90% nominal capacity | Capacity≥324Ah |

Low Temp performance | Stay 4 hours at -20±2℃ after standard charge, then discharge to end-off voltage at 0.2C, the discharge capacity ≥90% nominal capacity | Capacity≥216Ah |

Extruding (Single Cell) | Put the battery between the two extrusion planes of the extrusion equipment, gradually increase the pressure to 13kN, keep the pressure for 1min. Its longitudinal axis should be parallel to the extrusion surface and perpendicular to the extrusion direction. Only one squeeze test per battery | No fire, no explosion |

Thermal shock (Single Cell) | Put the battery in the heating box, temperature is increased to 130 °C ± 2 °C at a rate of (5 ± 2) °C/min and kept warm for 30 minutes, then remove and return to room temperature | No fire, no explosion |

Over-Charge (Single Cell) | The test should be conducted in an environment of 20±5°C. The battery discharges to the end-off voltage at 0.2C current first. Put the battery in a fume hood. Connect the positive and negative of the battery to the DC power supply. Adjust the output current of the power supply to 3C. The output voltage is not lower than 10V. Continuous charging for 7 hours or the voltage is not increase any more, current decrease to zero. | No fire, no explosion |

Forced discharge (single Cell ) | The test shall be conducted in an environment of 20±5°C. The battery shall be discharged to the end-off voltage at 0.2C current first, and then reverse charge to the battery with 1C current 90min. | No fire, no explosion |

Short Circle (single Cell) | After full charge according to the standard, put the battery with thermocouple in the fume hood (total line resistance is less than 50mΩ), short circuit the positive and negative poles, monitor the battery temperature during the test, end of the test when the battery temperature is lower than its peak value 10°C. | No fire, no explosion, the surface temp less than 150℃ |

Acupuncture (single cell) | The test should be conducted in an environment of 20±5°C. Charge the battery to the limit voltage according to the standard. A thermocouple is connected to the maximum surface area of the battery and place in a fume hood. A stainless steel needle with 3mm diameter is used to pierce the center of the largest surface of the battery at a rate of 20 mm to 40 mm/s and hold for 1 min. | No fire, no explosion |

Heavy Impact (Single Cell) | The battery is placed on a flat surface and a Φ15.8 mm steel column is placed in the center of the cell. The longitudinal axis of the steel column is parallel to the plane, allowing 9.1 kg of weight to fall freely from a height of 610 mm to the steel column above the cell center. | No fire, no explosion |

7. Transport

Batteries should be packed into boxes for transportation under the SOC of 20 ~ 50%. During transportation, severe vibration, impact or squeezing should be prevented to prevent sun and rain. It should be applicable to cars, trains, ships, aircrafts, etc. Ordinary means of transport.

8. Storage

The battery should be stored in a clean, dry and ventilated environment with a temperature of 20±5°C and a humidity of 65±20% RH. Contact with the erodible substance should be avoided. Keep away from fire and heat sources. Charging every 3 months during battery storage. In the process of battery processing, when using the stock cell and the battery delivery, all should follow the principle of "first in, first out"

9. Packing and signage

9.1 Packing

The outside of the packing box should indicate the product name, model number, quantity, gross weight, manufacturer and contact address, and the date of manufacture. There should also be necessary signs such as “Handle with Care”, “Fear of Wetness”, and “Upwards”. The signs of its packaging, storage and transportation shall comply with the provisions of GB-191-2000

9.2 signage

Each battery shall have the following Chinese information: product name, model number, nominal voltage, nominal capacity, positive and negative polarity trademarks and warning instructions, and manufacturing date, lot number, manufacturer name, (or serial number including the above data )

10. Remark

With the above, it can be used as a framework for the agreement between the supply and demand sides on the performance and inspection rules of battery products. If there is no new written agreement or change notice, will operate according this. If you find any problem with this specification, it must be approved by both parties before modifying

11. Appendix

11.1 Instructions for use and safety procedures

11.1.1 Recommended use

read the instruction manual and the surface of the battery carefully, before using the battery,

Please use the battery in normal indoor environment, temperature: 20±5°C, relative humidity: 65±20%

Keep away from heat and high pressure, avoid children playing with batteries, and do not beat the battery during use.

The battery can only be charged using the accessory charger. Do not put the battery in the charger for more than 24 hours.

Do not short-circuit the positive and negative terminals of the battery. Do not disassemble the battery yourself. Do not place the battery in a damp place to avoid danger.

When the battery is not used for a long period of time, please keep the battery in good condition and leave the battery in a half of SOC. Recharge it every 6 months. Do not wrap the battery with conductive material to avoid direct metal contact with the battery and damage the battery. Store the battery in a cool, dry place.

Dispose of the battery safely and properly. Do not put it into fire or water.

Danger warning

Do not disassemble and assemble battery: Inside the battery has a protection mechanism and protection circuit to avoid danger. Inappropriate disassembly will damage the protective function and cause the battery to heat, smoke, deform or burn

Do not short-circuit the battery: Do not connect the positive and negative terminals of the battery with metal. Do not store and move the battery together with the metal sheet. If the battery is short-circuited, excessive current will flow through it, which will damage the battery and cause the battery to heat, smoke, deform or burn.

It is forbidden to heat and incinerate the battery: heating and incineration of the battery will cause the battery separator to melt, lose safety function or electrolyte burning, and the overheat will cause the battery to generate heat, smoke, deformation or burning.

Avoid using the battery near the heat source: Do not use the battery in the vicinity of the fire source, the oven, or in excess of 80°C. Overheating will cause short circuit in the battery, causing the battery to generate heat, smoke, and deformation or burning.

Do not get wet the battery: Do not get wet or put the battery into water. Otherwise it will cause the internal protection circuit and function of the battery to be lost and abnormal chemical reaction. The battery may have heat, smoke, deformation or burning.

Attention

Note: avoid using batteries in strong sunlight and exposure to avoid heat, smoke and deformation, at least avoid battery performance degradation and life expectancy reduction.

Anti static: battery is equipped with protection circuit to avoid all kinds of accidents. Do not use the battery in the place where the static electricity is produced, because the static electricity is easy to damage the PCB, which causes the battery work to be abnormal, heat, smoke, deform or fire.

Charging mode: please use special charger and recommended charging mode to recharge the battery under the recommended environmental conditions.

Safe use protection: Please discuss with suppliers about the perfection of protection function, if battery is used for other equipment,.

The battery should be charged immediately, When the battery pack is under voltage protection.

Quality assessment

Quality inspection is divided into appraisal inspection and quality consistency inspection. Appraisal inspections are generally conducted during the Design setting, change design and production setting. Sampling plans, inspection items, orders, and rules for determination are determined by both the supplier and the buyer. In principle, the above performance tests should be included. The quality consistency inspections are divided into batch inspections and periodic inspections to determine whether or not the products can be qualified in the production process to ensure the continued stability of product quality. Please refer to GB2828-1987 standard implementation. Inspection items shall include appearance, internal resistance, rated capacity or 1C5A discharge capacity, etc.

11.3 Environmental requirements

This product meets ROHS environmental protection requirements

Warning: This design plan changes with product requirements without notice